Hong Kong Island, Hong Kong: The workshop at the heart of the city

- threefortheride

- May 16, 2016

- 3 min read

May 2nd, 2016: Three For The Ride arrives at Hong Kong Tramways’ depot. As we make our way towards the head office, we find ourselves immersed in a dense buzz of activity. Two mechanics are hard at work on the aluminum body of a tram. Another mechanic pulls a cart brimming with spare parts past us. Further off, a motorman repairs a traction system with a soldering iron.

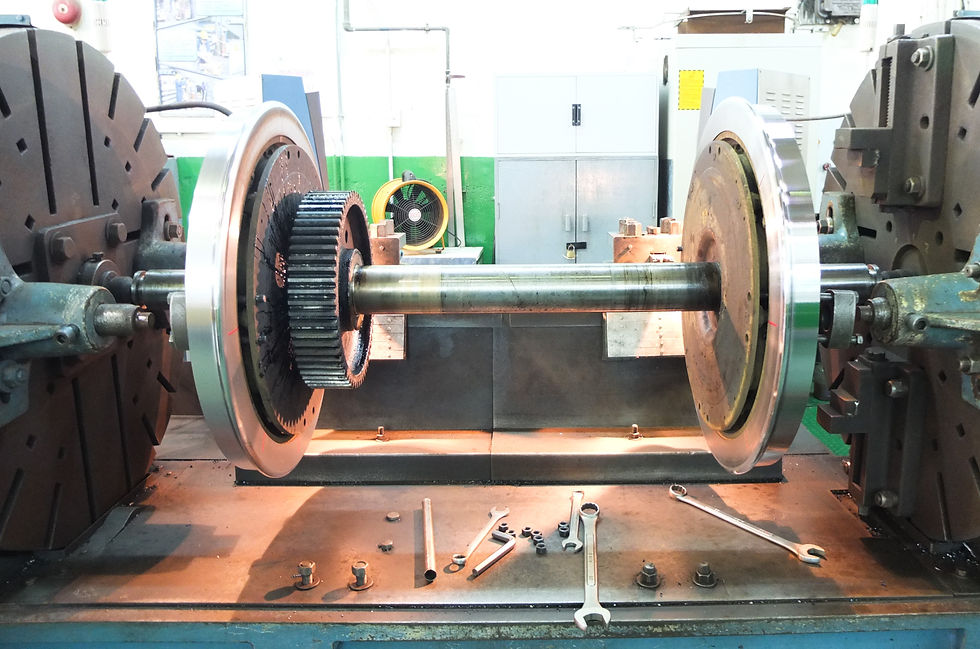

Hong Kong Tramways’ depot is also a workshop. In fact, all the tramcars are made here! Introduced to the world in 1904, Hong Kong’s double-decker tramway network is the last of its kind. Suppliers have gone out of business since decades, and it’s up to the workshop to produce each spare part it needs, from the wheels to the body of the tram.

This « can-do spirit » is the key to Hong Kong Tramways’ success story. At the head of the Engineering Department, the inventive and resourceful Steven Chan ensures that the modern tram remains Hong Kong’s most authentic and least expensive transport mode.

Steven Chan, Senior Engineering Manager for Hong Kong Tramways, in the workshop

“I started working for Hong Kong Tramways the 1rst of October 1996, on the day of the Chinese national celebration!”

Steven Chan can be proud of his work: in the span of twenty years, he has modernized the largest remaining fleet of double decker trams in the world.

“When I first joined the company, the equipment and the operating systems dated back to the fifties. The vehicles were made of wood, there was no signaling system, and switching tracks was done manually.”

“An accident finally made the company realize that they needed to modernize the trams. They hired me to lead the change, and left me a great deal of freedom in doing so.”

Steven Chan has kept this freedom of action up to today. The people of Hong Kong love the tram for its authenticity and for its cheap cost. Steven Chan has therefore two challenges. On the one hand, he must modernize the trams all the while preserving their historical character. On the other hand, he must do it incurring the least possible expenses, as the company is not funded by the state.

“One of my most important projects here is converting the entire fleet from a wooden vehicle structure to an aluminum vehicle structure. Our goal in doing so is to increase the cars’ life span, which is only 20 years for wood versus 40 years for aluminum. This reduces maintenance costs on the long term. As for the design, we first experimented with a model visually similar to a bus. But after having tested these first trams on the tracks, we finally decided to revert to the look of the historic trams.”

In Hong Kong Tramways’ workshop, no one has the final word. “Motormen love their company, because there is no engineer finalizing the design. Everyone works together to find it.” The 45 motormen on the team collaborate together to find solutions adapted to the equipment and the systems, as well as to the production tools – some of them almost a century old!

The Whitty Street tram depot

Transdev takes an active part in this resourceful mindset. « When they came into the company in 2009, Transdev allowed us to invest in a regenerative braking system. The system uses 25% less energy and uses up the motor slower, which reduces costs on the long term. »

In the midst of Hong Kong’s consumer society, Hong Kong Tramways has preserved a “can-do spirit” that is the key to its success with passengers. At the end of the sixties, most big cities abandoned their tramways for the benefit of the individual car. Having reached the limits of that model, many are now building tram networks anew. Hong Kong Tramways has successfully carried its network throughout the ages up to today.

The production of tram wheels in Hong Kong Tramways’ workshop

댓글